Why suspension?

A vehicle’s suspension system is a set of mechanical connections, springs, and dampers that connect the wheels to the chassis. It has two primary purposes:

First, to keep the cockpit (and the vehicle itself) steady by filtering out unwanted disturbances coming from a bumpy road, cornering, braking or acceleration. This helps deliver a comfortable, smooth, and pleasant ride. Not a must-have for rally drivers, who like to test their racing techniques.

Second, to maximize the contact between the tires and the road surface, providing steering stability and good handling (read: safety), in all driving conditions. Again, not essential for rally drivers, who prefer to ‘drift’ around the track.

Suspension springs and dampers

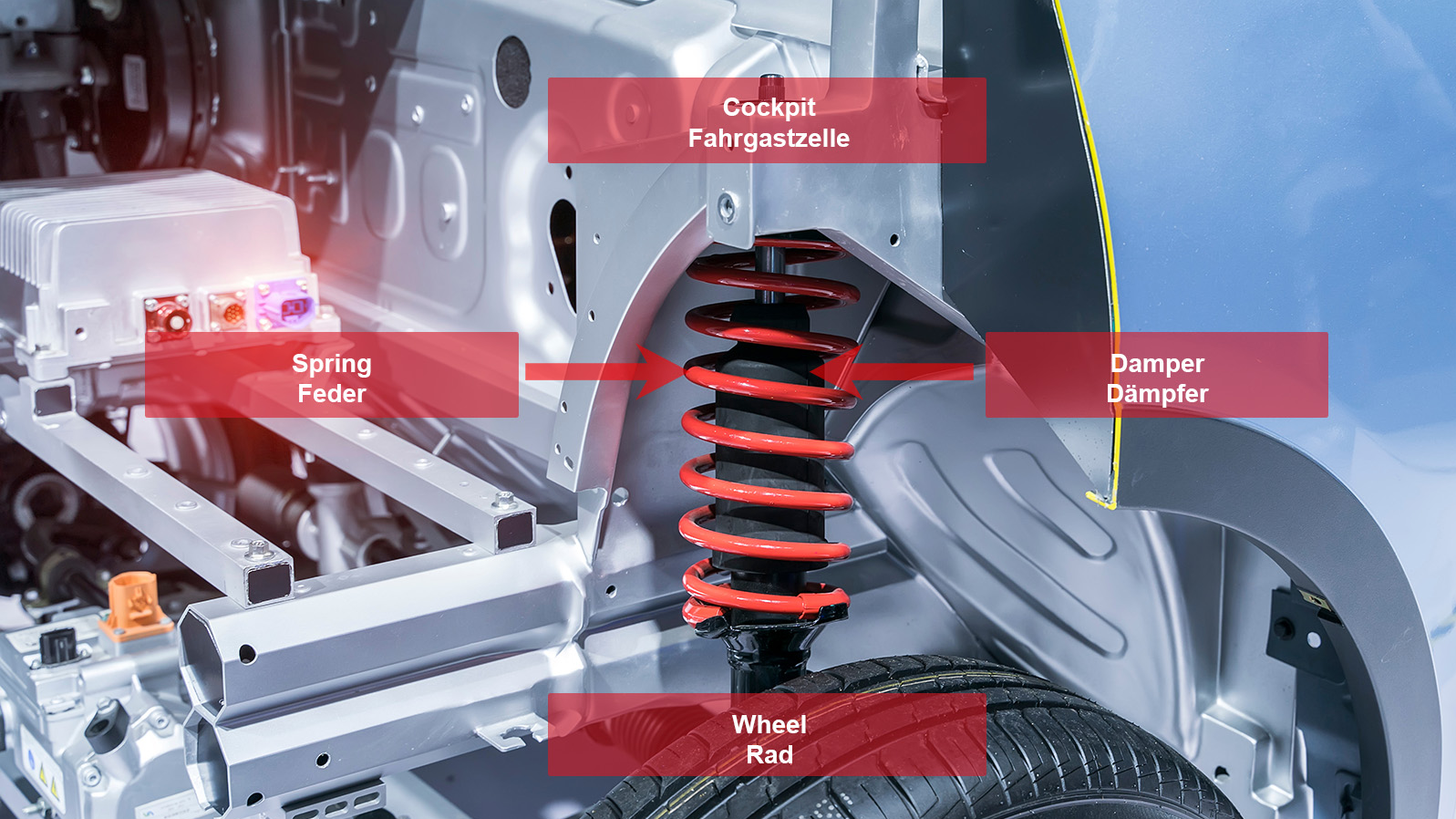

Springs and dampers connect the wheel to the vehicle or cockpit itself (see picture below).

SPRINGS

Springs compensate uneven road surfaces, filtering out any vibrations coming from the road generated by bumps, potholes, etc. More specifically, they compress as the wheel goes up – for instance when hitting a bump – and store energy while doing so. Springs expand as the wheel goes back down, releasing the stored energy.

Steel and air springs and how they compare

The most common springs on the market are steel springs. Their construction is very simple, as they’re made of thick steel wire formed into a ‘springlike’ shape. Steel springs are robust, offer great value for money, but they’re not “smart”; they cannot dynamically respond to changing conditions.

Air springs are smarter; they can react to the driving conditions ahead and keep the vehicle at a constant level, regardless of how heavy its load is. As the name implies, air springs have chambers filled with air (and with air being compressible it will behave like a spring).

Air springs can literally adjust the height of the cockpit by adding or removing air. For instance, when driving over a curb or moving through rough terrain the air spring is “pumped up” by adding air, causing the cockpit to rise. On the highway, at faster speeds, the air volume is reduced, lowering the vehicle body, and thus its air resistance. As a result, fuel or electricity consumption drops.

Steel springs are compressed with high load. This can lead to a reduced clearance and spring travel, and consequently reduced stability and comfort. Conversely, a heavy-loaded vehicle with air springs can simply add additional air to the chambers which lifts the vehicle back to the original level, maintaining comfort and safety.

Adjusting the springs for a perfect ride

It’s also possible to adjust the characteristic of the spring itself during driving (this is spring-rate adjustment ‘on-the-fly’). The air chamber can be split in segments, which can be activated or deactivated depending on the set-up needed. So, there is an “always active chamber” which offers a small air volume and consequently a “firm” setup. By activating further segments the active air volume increases (which makes the setup “smoother”). The smoother the setup is, the more effective the filtration of impacts coming from obstacles, but the “spongier” the ride feels. When driving offroad a “smooth” setup is preferred.

When handling emergency maneuvers, a “firm” set up is the better choice.

DAMPERS

Dampers control how fast the spring is allowed to compress and extend. It does so, transforming kinetic energy (“movement”) into heat.

There are two types of damping actions: rebound damping and compression damping.

First, let’s take a closer look at rebound damping. We know that the spring compresses and expands depending on road conditions. By nature, the spring expands very quickly, resulting a bouncing effect, similar to that of a rubber ball hitting the floor. The damper slows down the expansion speed of the spring, avoiding the “rubber-ball-effect”.

Compression damping is used in dynamic driving situations. During braking, the springs are compressed at the front and fully extended (floating) at the back, and vice versa during acceleration. When the vehicle turns a corner, the outer springs will compress while the inner springs will expand.

A firm compression makes the suspension less sensitive to bumps and potholes but helps to keep the cockpit steady in above mentioned situations.

If you are a rally driver who loves jumping, a firm compression setting is even more important to land safely without causing the spring to overload.

Sophisticated dampers can adjust the level of damping during the ride and respond dynamically to changing driving conditions. For instance, applying normal damping while driving in a straight line at constant speed (highway), and increase the level of damping when turning, braking, or accelerating as described above. Just like with air springs, it is advised to use “firm” and “smooth” settings depending on the road conditions.

Smart suspension systems

Really smart suspension systems combine air springs and adjustable dampers with electronics and cameras that scan the road. These sophisticated systems automatically adjust the suspension-setup in milliseconds for perfect performance. An example: Let’s assume the camera detects a pothole. The rebound setting of the dampers is changed to quick expansion, so that the wheel can follow the dip in the road while maintaining constant connection to the surface and keeping the chassis stable.

So, there you have it, a short explanation on the general working principles and features of a suspension-system. If you enjoyed reading this article or have any questions, please leave a comment. There’s a lot more to suspension than meets the eye!

Curious about Kendrion’s suspension system solutions?