Reliable Components and Tailored Solutions for Food & Beverage

Kendrion develops customized systems that make production processes in the food and beverage industry more efficient, safer, and more sustainable. Our technologies in the fields of valve technology, actuation, and control ensure precise, hygienic, and reliable motion and regulation in modern machines and equipment.

Whether it’s locking mechanisms for commercial ovens, security systems for vending machines, control solutions for filling processes, or inductive heating for consistent process temperatures – Kendrion provides dependable components that ensure safe and efficient production.

Solenoids locks SL & AL for in-store baking ovens

Kendrion is an expert in secure door locking systems that meet the highest standards of safety and reliability. For in-store baking ovens, the SL7010 magnetic lock was developed, featuring a solenoid actuator for quick and quiet unlocking and an integrated microswitch for precise position detection.

Your Benefits

- Impulse driven – powerless, also in locked position

- Self locking (SL) or actively lockable (AL) by electrical impulse

- Emergency opening feature

- Integral detector to determine locked position

- Secure and functional also under high pull-load

Compact Lock CL for food vending machines

Food vending machines provide fresh snacks and beverages around the clock without the need for staff. To ensure safe and reliable operation, Kendrion offers a compact locking system that is tamper-resistant and protects the machine from unauthorized access.

Your benefits

- Designed for limited installation space

- emergency opening feature

- integral detector to determine locked position

- highly shock resistant

- door hook included

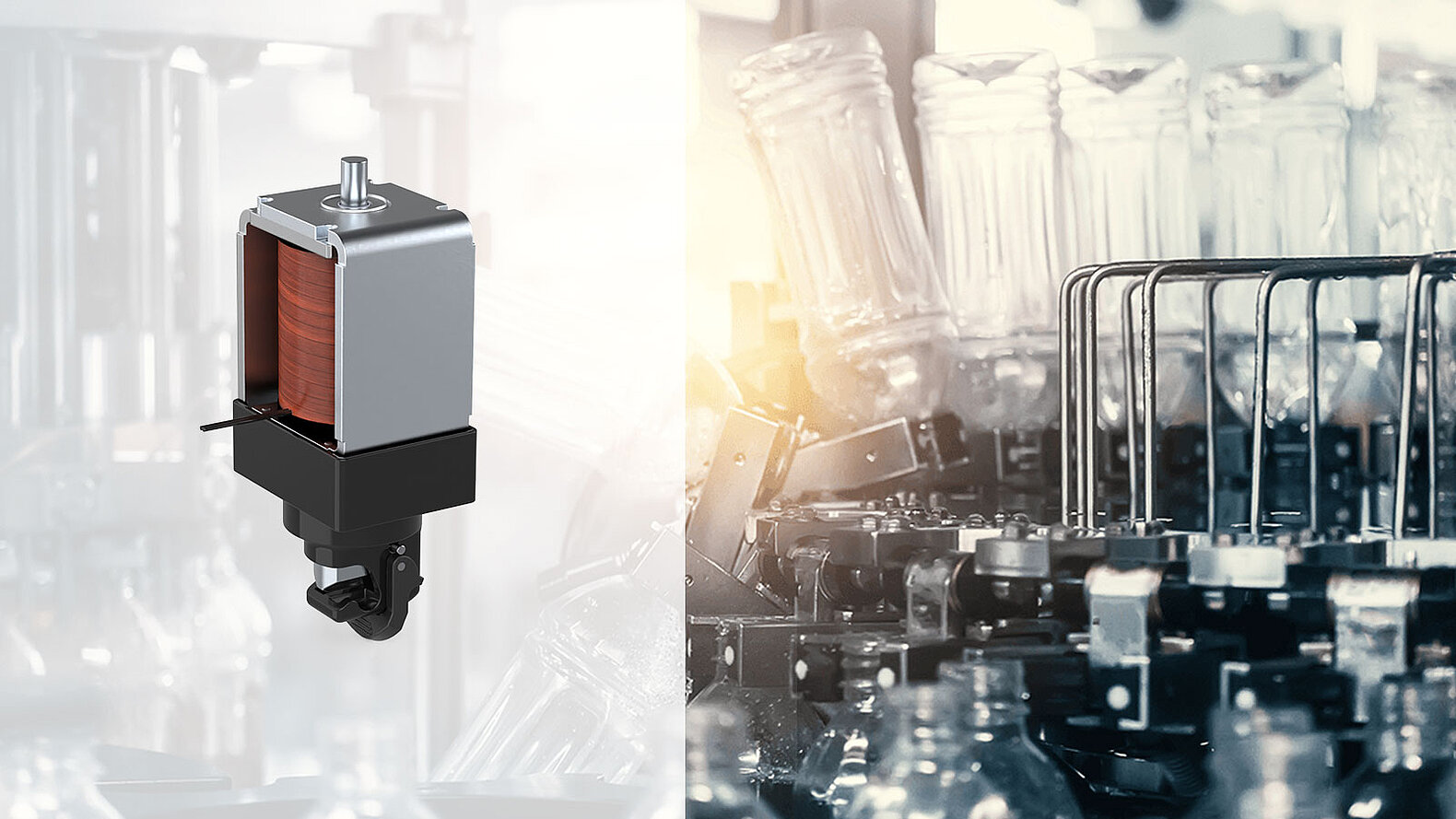

Optimizing bottling processes with the Power Pinch Valve

The Power Pinch Valve is a cutting-edge tube pinch valve that offers precise flow control and significant cost savings in filling processes. By allowing the use of cost-effective tube materials like PVC, this valve helps to reduce operational costs. It can easily accommodate diameters ranging from 4-7mm, thanks to its impressive clamping force of 42 N.

Your Benefits

- Ideal for dosing liquid and viscous media

- Suitable for hygienically critical applications or for aggressive cleaning agents

- Suitable for feeding hot liquids, as the medium is completely separated from the valve.

Inductive heating in conveyor ovens

Kendrion offers an induction-based modular heating system with up to 100kW power, which can be used for example in wafer baking machines. For this purpose, precisely fitting surface inductors are used that provide the required heat in the baking plates precisely, quickly and evenly, thus ensuring a perfect baking result.

Your Benefits

- Replacing oil or gas with high energy efficiency > 95%

- Optimum temperature control (±1,5°C)

- Cleanliness and safeyt in food handling

- Customized solutions for surfaces and rollers

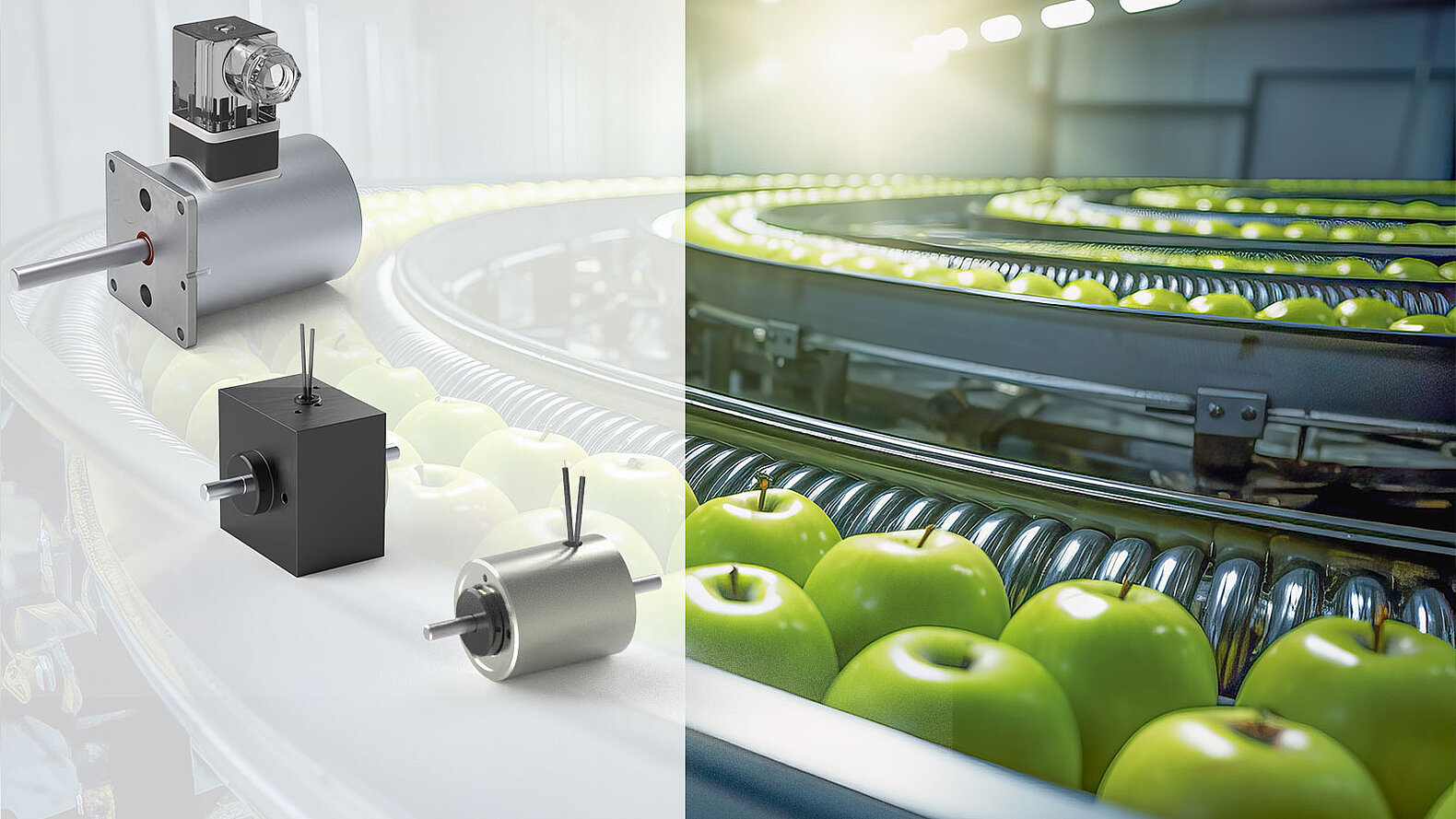

Rotary solenoids for sorting & conveying processes

Kendrion's rotary solenoids ensure fast and precise flap actuation in fruit and vegetable sorting machines, providing a clean and reliable solution for food handling.

Your Benefits

- Very fast actuation

- Precise and repeatable

- Electrical actuation is a simple and clean solution for handling of food products

Pilot control for process valves in breweries, dairies, and the beverage industry

Pilot control valves are an important part of automated matrix-piped process plants. Our product is applied in breweries, dairies, the beverage industry and in the pharmaceutical industry. A combination of a 3/2 way pilot and main control valve controls tops of different process valves. With the Kendrion valve, it is possible to achieve higher flow rates with low power consumption in a compact design.

Your benefits