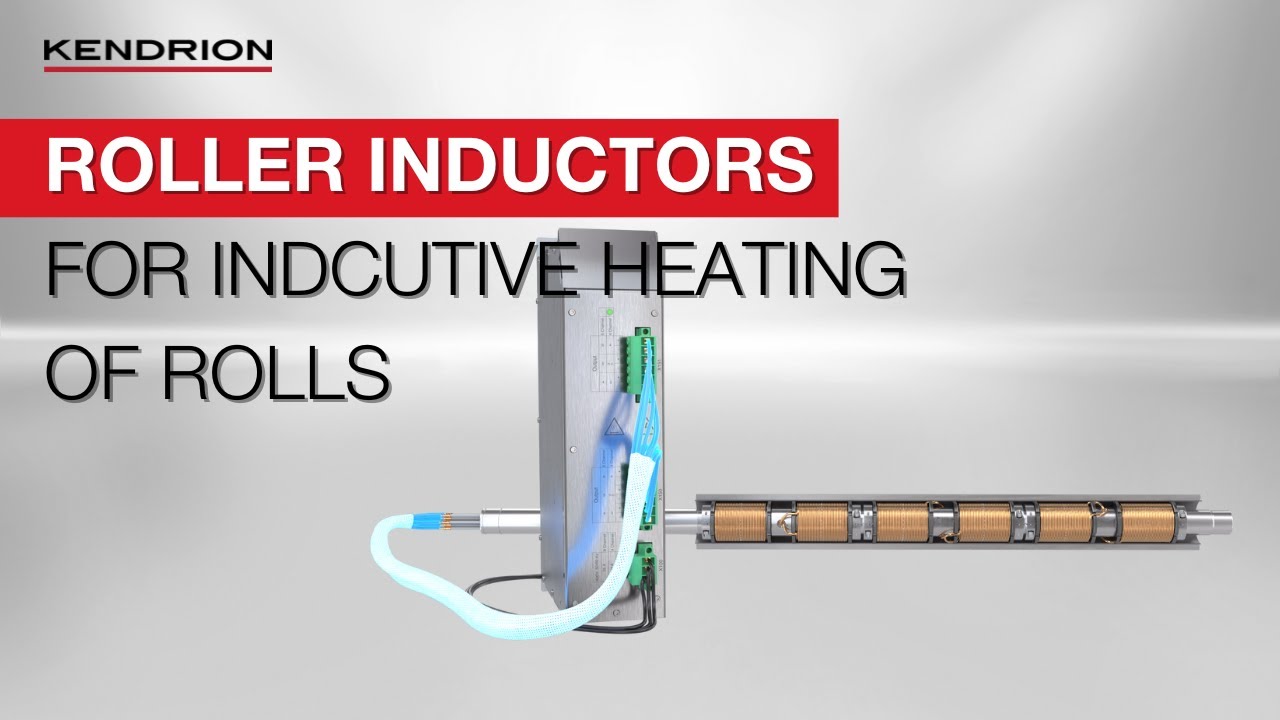

Efficient heating rolls with roller inductors from Kendrion

Our inductors for heating rolls and other heated rotating rolls – for example in calenders – ensure precise temperature control and even heat distribution in a wide range of industrial applications.

Modularly designed individual inductors allow individually controllable heating zones to be created. These segments are mounted on a shaft to form a heating mandrel and inserted into the rotating heating roller as a stationary unit. In addition to the heating roll, the inductors are used in other heating systems such as base cylinders, embossing cylinders, current conductive rolls, smoothing rolls, chill roll cylinders, laminating rolls, and calender rolls.

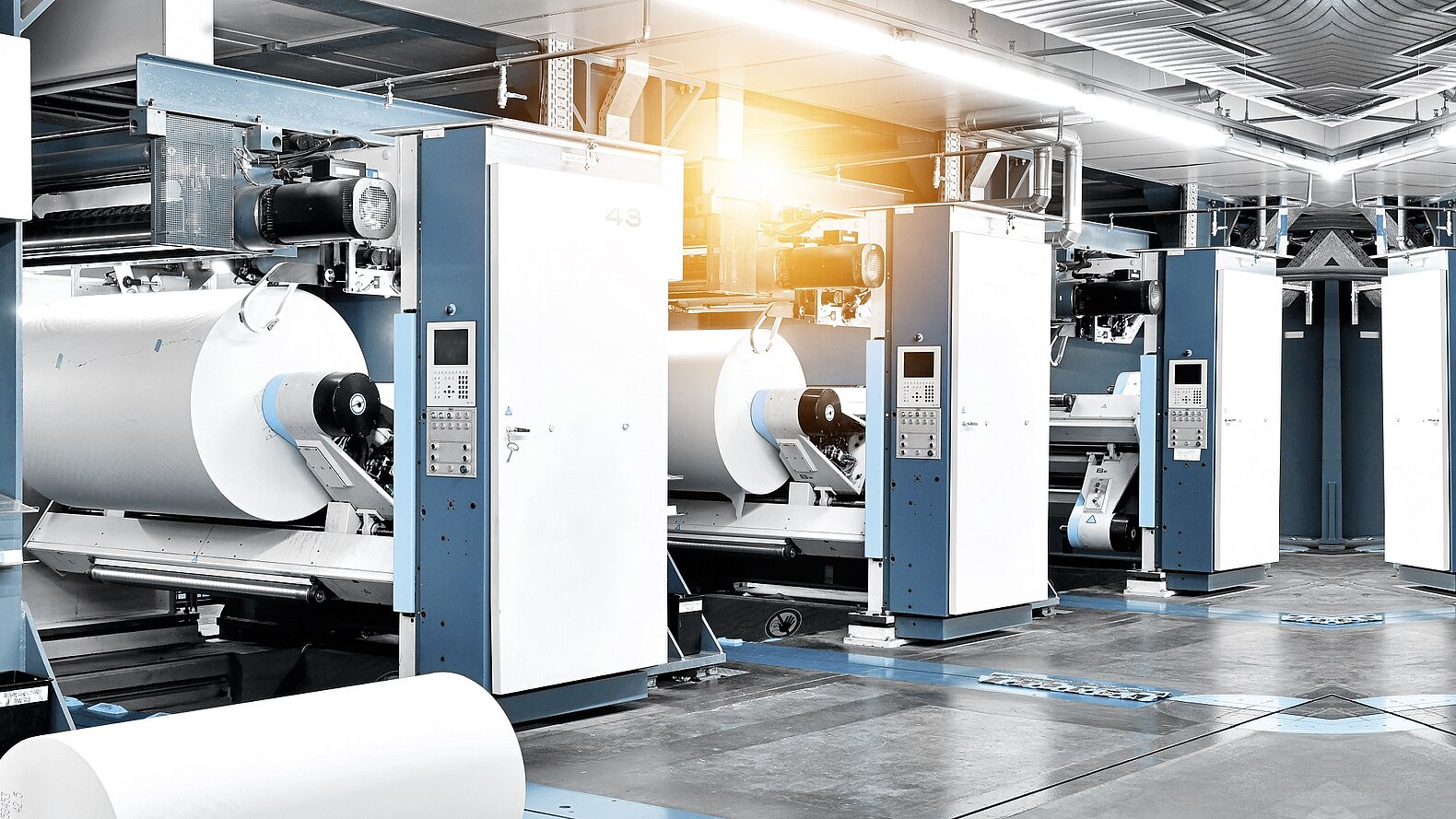

Whether for the plastics and rubber industry, textile production, paper and packaging processing, metalworking or the food industry – we offer you the right solution.

Maximum efficiency, minimum maintenance – with inductively heated heating rolls

Unlike conventional heating rolls, which use thermal oil, water, or steam, inductive heating requires neither complex installations nor costly approval procedures. Leakage risks and liquid media are a thing of the past – protecting the environment and health while reducing operating costs.

Inductively heated heating rolls with our application-specific inductors offer decisive advantages over classic heating rolls with heating rods or liquid media:

Maximum energy efficiency through direct, low-loss energy transfer

Fast and precise temperature control without delay

Maintenance-free and low-wear – no slip rings or seals

Long service life thanks to contactless technology

Flexible temperature range for a wide variety of production processes

Thanks to our specially adapted, fieldbus-compatible induction generators, integration into your machine is quick and easy. On request, we can also supply the heating rolls as a completely autonomous unit with integrated control and operating display.

Inductively heated rollers: benefits at a glance

- Fast and even heating thanks to induction technology

- Low energy consumption → lower operating costs

- Low maintenance and therefore less downtime

- Longer service life compared to conventional heating methods

- Contactless energy transfer from the stationary inductor mandrel to the rotating jacket

- Wear-free thanks to contactless heating

- Fieldbus-compatible: Profinet®, CANopen, EtherCAT®

- Reduced risk of injury (e.g. from hot oil)

- Emission-free heating

- No cooling unit required

Are you looking for technical informations about our roller inductors?

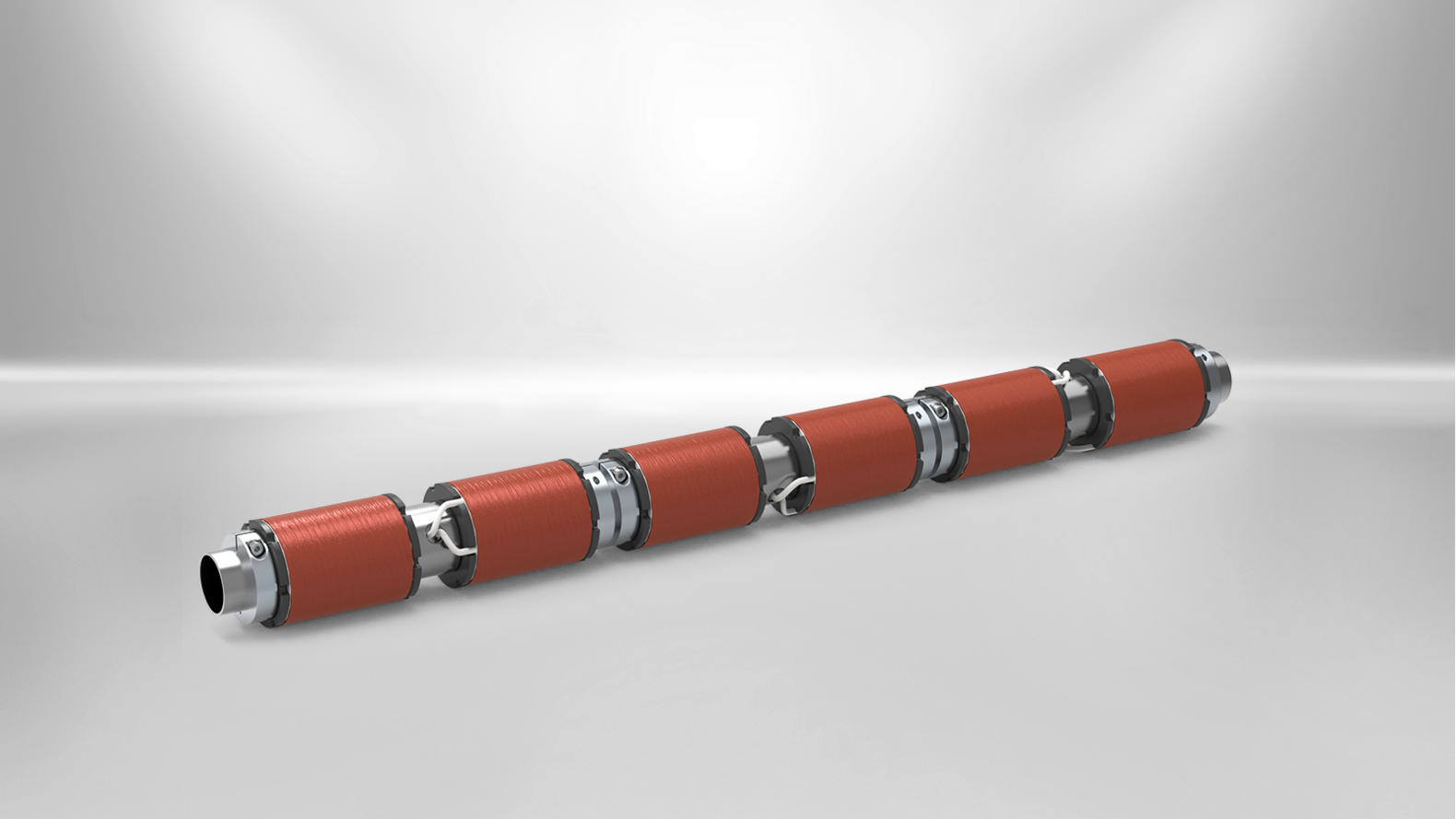

Our Standard roller inductors are available in different designs.

Inner diameter of the roller from 60mm to 480mm

Heated section up to 250mm

Temperature range up to 300°C

What are the advantages of induction-heated rollers compared to liquid media such as thermal oil, water, or steam?

Induction-heated rollers offer contactless, wear-free energy transfer and enable fast and precise temperature control. Unlike liquid media, they eliminate leakage risks, complex approval procedures, and costly maintenance under the Pressure Equipment Directive.

What are the disadvantages of liquid media heating systems?

Rollers using thermal oil, water, or steam require complex installation and regular, expensive maintenance. They carry leakage risks that can harm both the environment and health. In addition, temperature control is often sluggish and imprecise.

Why are electric heating rods at a disadvantage in roller heating?

While electric heating rods are easy to install, they have higher energy consumption, limited temperature ranges, and require wear-prone slip rings for energy transfer. Temperature regulation is inaccurate and sluggish, and maintenance or replacement is often time-consuming.

Wie wirken sich induktiv beheizte Walzen auf Betriebskosten und Nachhaltigkeit aus?

Dank der hohen Energieeffizienz sinkt der Stromverbrauch, während Wartungs- und Stillstandskosten durch die verschleißfreie Technologie reduziert werden. Das macht induktiv beheizte Walzen zu einer nachhaltigen Lösung im Vergleich zu herkömmlichen Heizmethoden.