Spring-applied brakes for the future of electric intralogistics

The industrial truck industry is undergoing dynamic change: increasing electrification is fundamentally altering design, application profiles and performance requirements. Today, electric industrial trucks set standards in energy efficiency, precision and ease of use. They enable emission-free operation in indoor areas, offer sensitive and precise vehicle control and significantly reduce maintenance costs compared to combustion engine variants. At the same time, the demands on availability, safety and performance in demanding multi-shift operation are increasing.

The application determines the brake – and the brake determines safety

Electrification is bringing electric drive systems and their safety components even more into focus. Holding and safety brakes contribute significantly to the operational safety and functional stability of vehicles, especially when it comes to safe stopping on slopes, precise positioning of loads and emergency stops under high loads.

Spring-applied brakes have established themselves as the preferred technology: they offer high emergency stopping energy, operate reliably and are virtually wear-free – even during long operating times, high cycle rates and demanding environmental conditions. Their robust, fail-safe operation makes them the first choice for modern electric industrial trucks that must ensure maximum safety and efficiency in internal material flow.

Spring-applied brakes for counterbalance forklifts

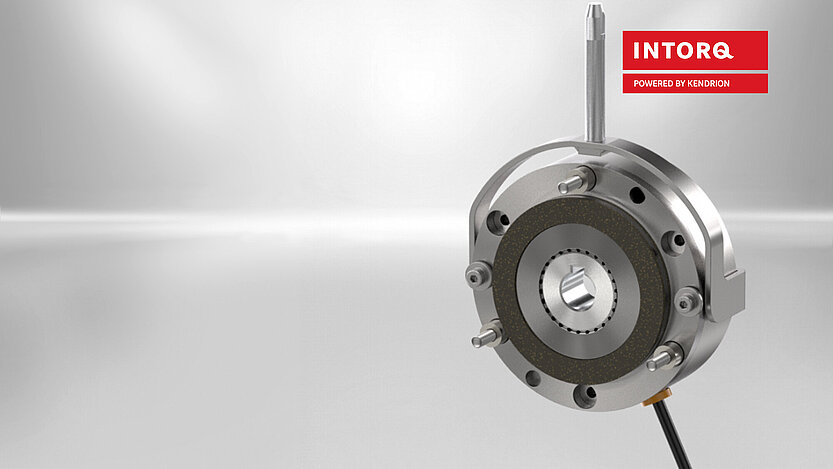

When developing the BFK552, the focus was on combining an extremely compact design with maximum performance to make optimum use of the limited installation space available in electric forklift drives.

With an overall length of just 43.7 mm and a braking force of 60 Nm, the BFK552-12 is the perfect fit for a variety of vehicle configurations. Thanks to its high IP66 protection rating, the brake is optimally protected against dust and water jets, and can reliably withstand the harsh conditions of internal factory transport. Over-excitation and holding current reduction enable the brake to be released quickly and safely while reducing energy consumption in the holding state.

Here you will find the technical data, STEP files and operating instructions for the BFK552-12.

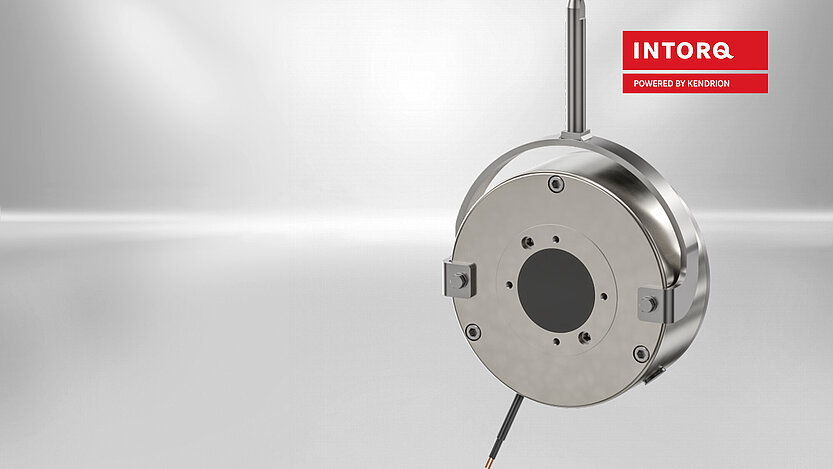

With the BFK457, Kendrion provides a modular and powerful design-in platform that can be efficiently adapted to different vehicle and drive concepts.

The BFK457-14 delivers an effective braking torque of 90 Nm, supporting drive trains with increased torque requirements. It really comes into its own in counterbalance forklifts, where large masses need to be braked safely at higher driving speeds. Details such as integrated fasteners and a defined air gap facilitate assembly and adaptation to customer-specific requirements, from the prototype phase to series production.

Here you will find the technical data, STEP files and operating instructions for the BFK457-14.

Spring-applied brakes for reach trucks

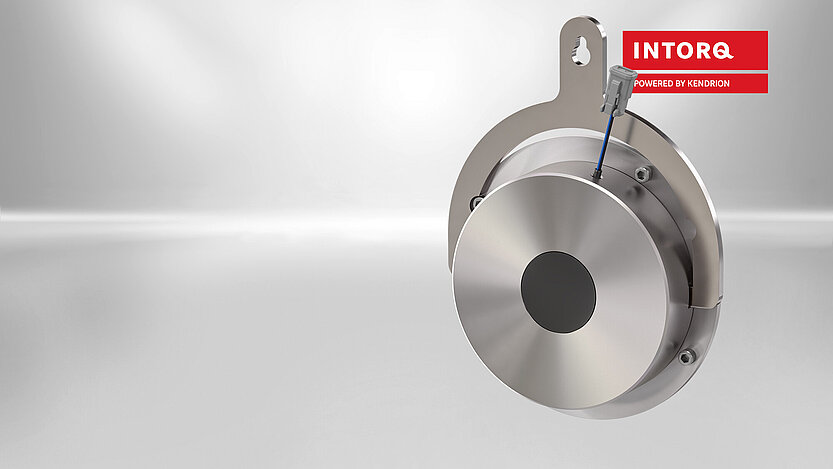

The BFK457 holding brake series is also the perfect choice for reach trucks. Thanks to its modular design, it can be optimally adapted to this vehicle class, ensuring safe holding and controlled braking during fast lifting and driving cycles.

The BFK457-12 with 46 Nm is used for applications requiring a lower torque, while the BFK457-14 with 90 Nm is used for more powerful drives.

Installation-friendly features such as integrated fasteners and a defined air gap reduce installation time and facilitate customisation.

Technical data, STEP files and operating instructions can be found here.

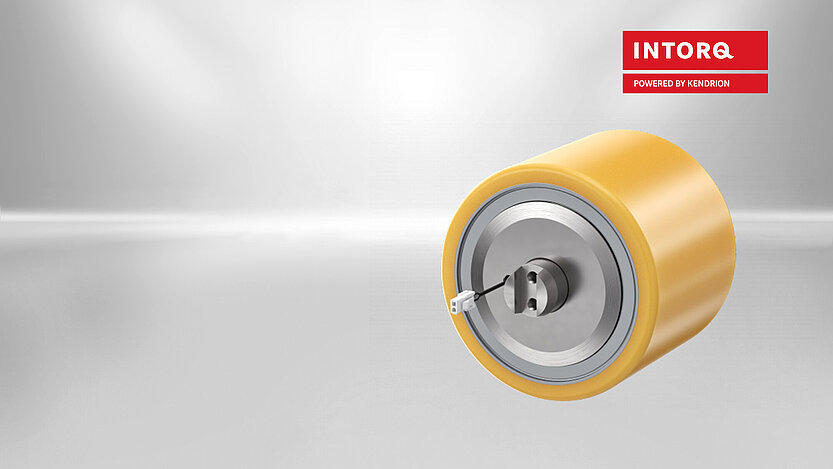

Spring-applied brakes for pallet trucks

The BFK557-08 holding brake from the BFK557 series is specially designed for pallet trucks equipped with speed-controlled traction drives in FI mode, enabling sensitive and energy-efficient handling. This means that the BFK557-08 can be integrated without additional effort and works reliably even with frequent start-stop cycles. As a fail-safe spring-applied brake, it also offers high emergency stopping energy, is flat and space-saving, maintenance-free and quick to install.

Here you will find the technical data, STEP files and operating instructions for the BFK557-08.

With its space-saving design and a braking torque of 12 Nm, the compact BFK457-08 safety brake from the BFK457 series is ideal for integration into electrically powered pallet trucks. Like all models in the series, it is particularly easy to install thanks to integrated mounting screws and a defined air gap. It is also maintenance-optimised, as the rotor can be easily replaced if necessary. For particularly low-noise applications, the BFK457-08 is also available as a noise-reduced double brake with <50 dB(A).

Here you will find the technical data, STEP files and operating instructions for the BFK457-08

Spring-applied brakes INTORQ BFK457

Ideal for integration into forklift trucks

These electromagnetically released spring-applied brakes can be used wherever rapid deceleration of moving masses or controlled holding of masses is required. Since the braking force comes from pressure springs, the braking torque, which is generated by friction, is available when no current is applied – even in the event of a power failure.

To safely stop and hold the loads, e.g. at a ramp, the INTORQ BFK457 is installed in the drive unit to ensure work safety during operation. Quick mounting with integrated mounting screws and fixed air gap make this spring-applied brake even more attractive.