Inductors for contactless heating

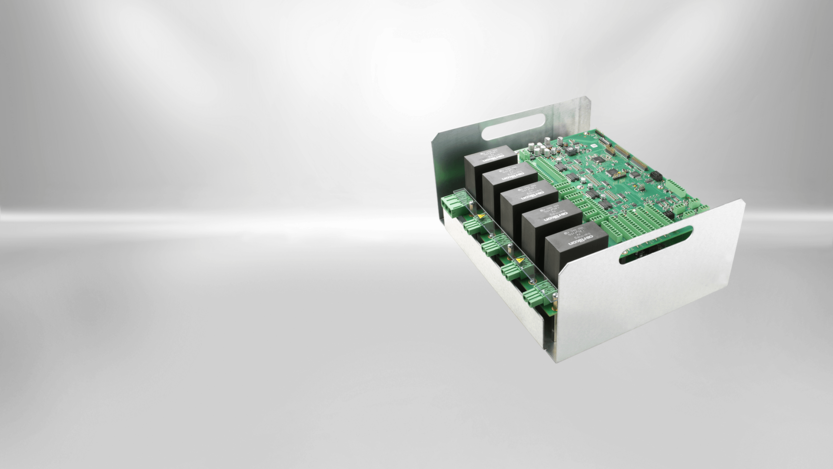

For the design of the inductors our engineers use numerical methods of field calculation. This enables us to adapt the inductors to the respective customer requirements. With our inductors, process temperatures of approx. 250°C can be reached in continuous operation. An additional water cooling is not necessary. We focus in particular on a homogeneous heat input.

Benefits at a glance

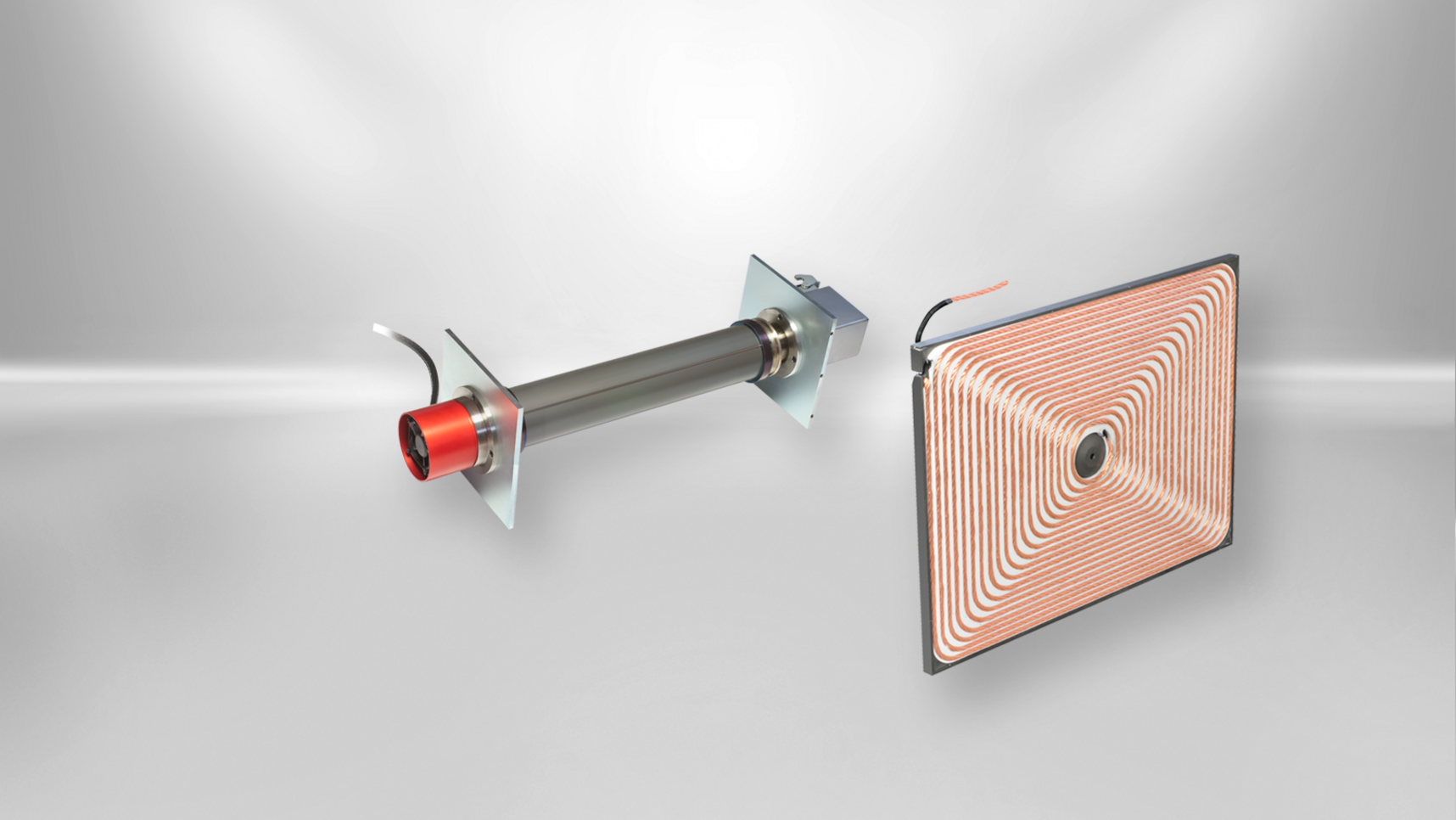

- Roller inductors from 60mm diameter & contactless energy transfer

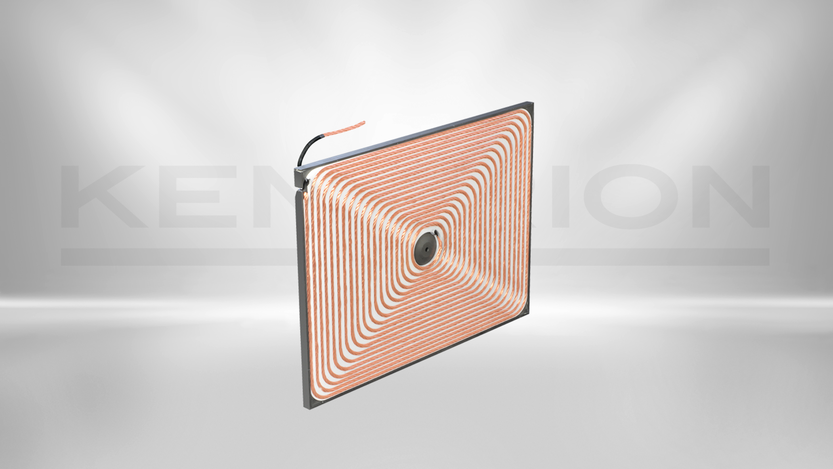

- Surface mount inductors individually adapted to the workpiece

- Optimal temperature control & uniform heating

- Fieldbus compatible: Profinet®, CANopen, EtherCAT®

- Reduction of the risk of injury (e.g. by hot oil)

- Emission-free heating

- No additional cooling unit necessary