The PDM bistable rotary solenoid – an efficient solution for automation and intralogistics.

Kendrion develops and manufactures bistable rotary solenoids specially designed for use as electromagnetic sorting switches in industrial automation and intralogistics systems. They enable fast and reliable control of the transport direction through targeted switch settings and are therefore ideal for use in dynamic intralogistics systems.

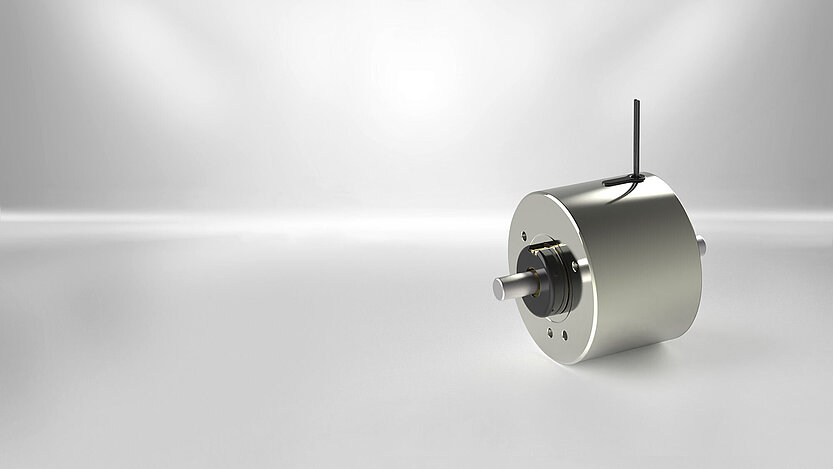

Precise rotary motion with a long service life

The PDM series is based on polarized rotary solenoids that perform a defined rotary motion of up to 60°. Thanks to the bistable design, the start and end positions are held securely with a high holding torque without the need for a permanent power supply. By reversing the polarity, the actuator achieves switching times of less than 10 milliseconds. Kendrion guarantees a maintenance-free service life of at least 100 million switching cycles.

Pneumatics-free intralogistics – efficient and sustainable

Whether for fast sorting, separating, or ejecting, PDM rotary solenoids offer a highly dynamic and reliable solution for a wide range of tasks in intralogistics. Their biggest advantage: they completely replace pneumatic actuators, enabling operation without a compressed air supply for compact, energy-efficient overall solutions.

Technical Features at a Glance

- Switching time: < 10 ms

- Rotation angle: up to 60°

- Holding torque: up to 1 Nm

- Nominal voltage: 24 V or 48 V DC

- Durability: > 100 million switching cycles

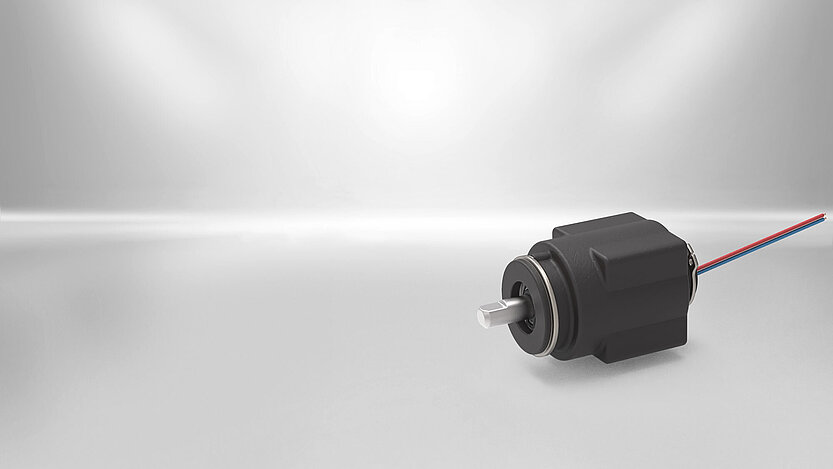

- Protection class: IP50 standard; upgradeable to IP65 with housing

- Optional Hall sensors for end-position feedback

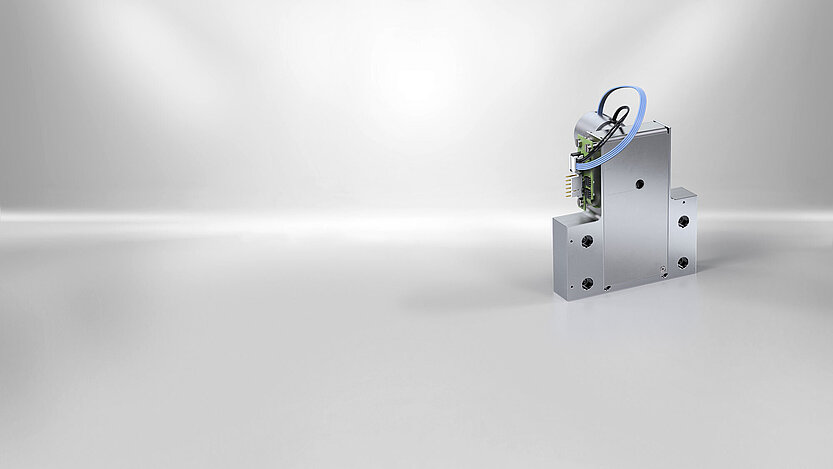

- Robust aluminum housing with integrated damping and ball bearings

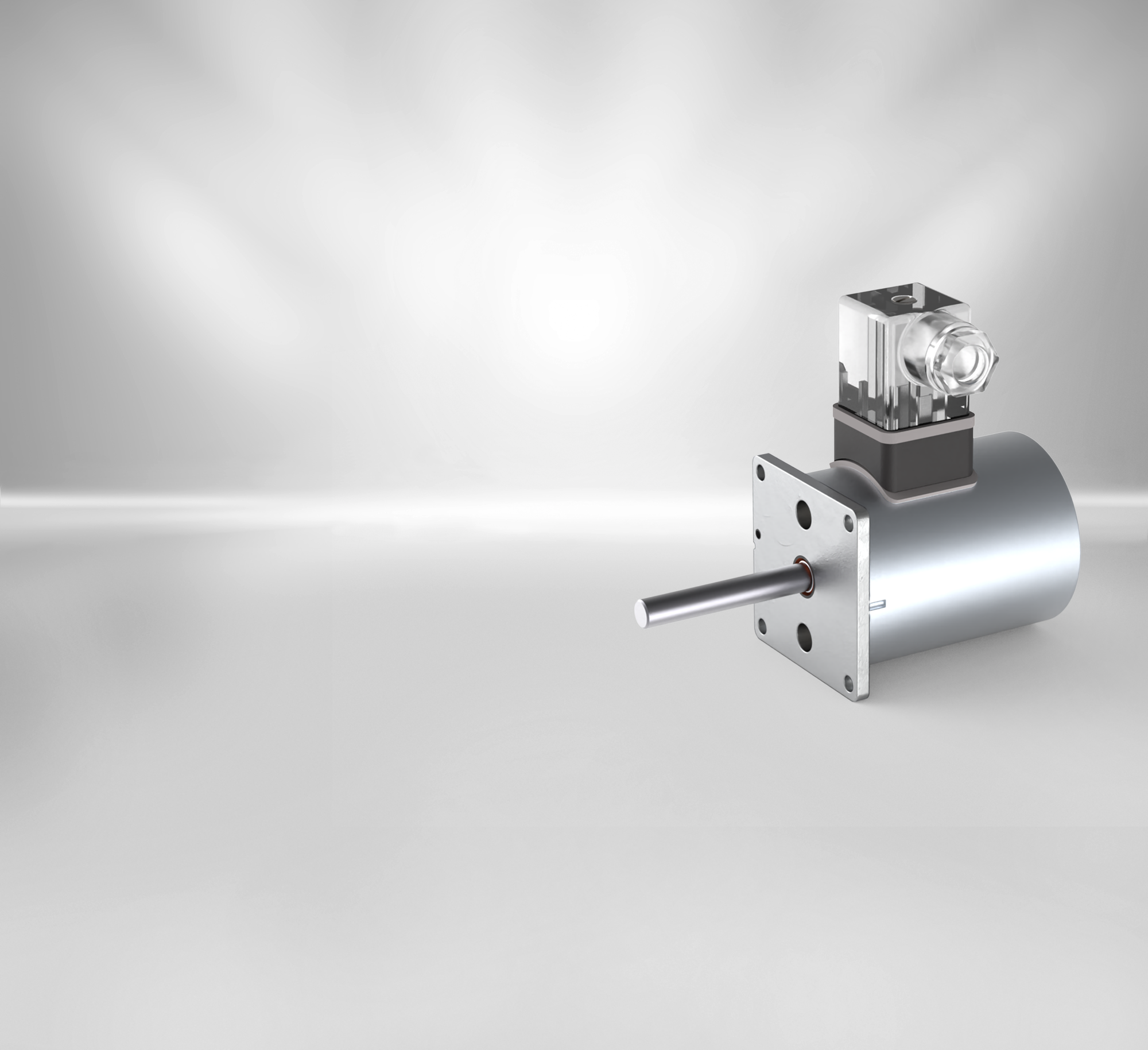

Bistable Rotary Solenoids – Kendrion PDM Series

The bistable rotary solenoids of Kendrion’s PDM series are ultra-fast switching actuators engineered for high-performance sorting and actuating tasks. With switching times of less than 10 milliseconds, items such as letters, banknotes, or parcels can be sorted with exceptional speed and accuracy. This high switching speed is achieved by reversing the polarity of the stator coils, while permanent magnets ensure reliable positioning in both end states.

Functional Principle of the PDM Rotary Solenoids

The electromechanical design of the PDM series shares many characteristics with small electric motors. Each unit consists of:

A stator with multiple coils

A polarized, freely rotating rotor

Two mechanical stops that define the start and end positions

By reversing the current direction in the stator coils, the rotor is quickly driven to its new position. The bistable design ensures that both end positions are held securely with high holding torque, enabled by the attractive force between the stator and the neodymium-based permanent magnet rotor—without requiring continuous power.

Tailored to Your Needs

Thanks to the modular construction of the PDM series, customer-specific adaptations are easy to implement. Whether you need custom torque settings, housing modifications, or integrated sensors, Kendrion offers tailored solutions to match your exact application requirements.

Technical Data (alternative specifications on request)

| Type | Diameter | Supply Voltage | Power | Rotation angle | Switching time | Currentless holding torque |

|---|---|---|---|---|---|---|

| PDM050 (bistable) | 50mm | 24-48V DC | 60-100W | max. 40° | 10-20ms | bis 0.15 Nm |

| PDM050 (monostable) | 50mm | 24-48V DC | 60-100W | max. 30° | ca. 20ms | bis 0.4 Nm |

| PDM060 (bistable) | 60mm | 24-48V DC | 96-120W | max. 30° | 10-20ms | bis 0.9 Nm |

| PDM080 (bistable) | 80mm | 24-48V DC | 84W | max. 40° | ca. 20ms | bis 1.0 Nm |