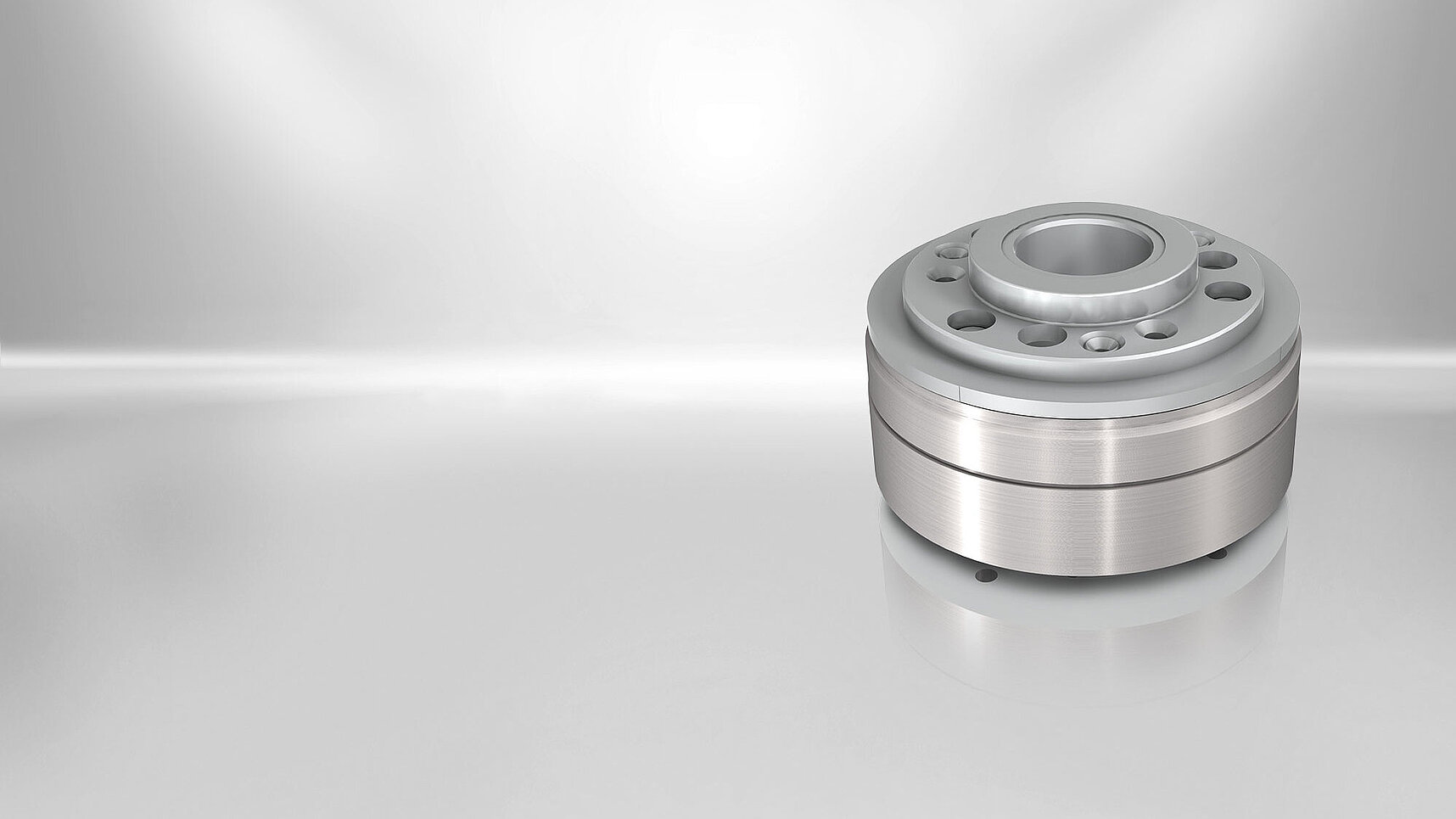

Our High Torque Servo Brake – Maximum performance for demanding applications

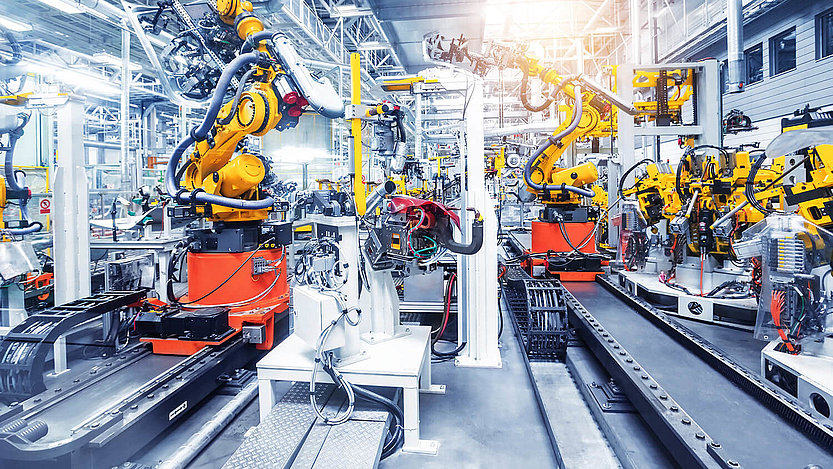

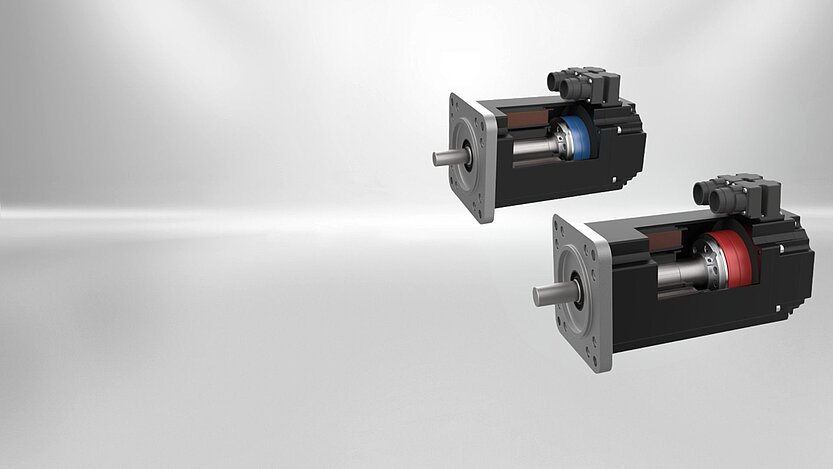

When maximum performance and reliability are required, the permanent magnet brakes of the High Torque Line impress with their outstanding properties. Thanks to their high power density, wear-free and residual torque-free operation, and short switching times, they are the ideal solution for powerful servo motors – for example in robotics, medical technology, or mechanical engineering.

While conventional permanent magnet brakes reach their limits with large voltage tolerances or extreme temperatures, the High Torque Line overcomes these restrictions with a patented magnetic circuit design. This optimizes the magnetic flux when the brake is opened, enabling reliable operation down to -60 °C without any loss of performance.

The High Torque brake uses a permanent magnetic field to generate braking force and is released by an electromagnetic counterfield. This ensures backlash-free, residual torque-free, and precise operation. The compact design with integrated excitation winding and robust armature system ensures high switching frequencies, maintenance-free operation, and consistent performance over the entire service life.

ONE Technology - The perfect duo!

The smart solution for mid- and low-torque motors.

Catch the first reveal of our next innovation exclusively at SPS!

Get your free SPS entry ticket!

Features at a glance

- Higher torque with equal size compared to classic permanent magnet brakes

- High and more stable torque due to innovative magnetic circuit

- Extended lifetime up to 2,000 emergency stops

- Extended temperature range down to -60°C

- Torque transmission without backlash

- Residual torque-free opening regardless of mounting position

- Wear-free at dynamic changes of direction

- Brakes factory-sided grinded & torque tested

- 13 sizes available

Technical Details

| Description | Value | |

|---|---|---|

| Operation mode | Holding brake with emergency stop function | |

| Designs | 13 sizes | |

| Standard nominal voltage | DC 24 V | |

| Protection class | IP 00 | |

| Thermal class | F (155°C) | |

| Torque range | 0.1 Nm - 280 Nm | |

| Duty cycle | 100% | |

| Nominal backlash | 0° | |

| Ambient temperature | 40 to +120°, optional -60°C |

Visit our Kendrion ProductFinder

Find technical data and product-specific information about our brake portfolio in our ProductFinder!

To the product FINDER for BRAKES

Brake Design and Operating Principle of the High Torque Line

The High Torque Line is designed for integration with servo motors. Mounting is possible on either the A- or B-side of the fixed bearing. It can also be integrated into non-motor applications, e.g., hand-guided tripods.

Operating Principle

The High Torque brake is designed to operate dry. A permanent magnetic field generates the force that produces the braking effect. To neutralize the braking action, the magnetic flux of the permanent magnets is canceled by an alternate electromagnetic field (electromagnetically released system). The zero-backlash connection between the armature and the flange hub ensures the reliable release of the high-torque brake with zero residual torque and the transmission of brake torque to the machine shaft (e.g., motor shaft) with zero backlash. Thanks to these features, high torque brakes are ideal for servo motor applications.

Brake Design

The field coil is firmly fitted between the housing and flange of the High Torque Brake. The flying leads required to connect the field coil exit at defined positions on the brake. Permanent magnets installed axially between the housing and flange generate the magnetic field required for braking. The armature connects with the flange hub via segmental springs and rivet fasteners, establishing an axially movable, torsion-proof, and friction-free connection. This ensures zero residual torque during horizontal or vertical operation of the brake. The air gap "s" between the armature and the housing of the high torque brake is automatically adjusted during mounting (e.g., due to mounting tolerances). The flange hub attaches to the machine shaft (e.g., the motor shaft) in a way that establishes a torsion-proof, axially fixed connection. The permanent magnetic field pulls the armature into frictional contact with the housing and flange. The resulting friction force generates the brake torque. When DC voltage is applied to the field coil of the high torque brake, the alternating electromagnetic field offsets the force exerted on the armature by the permanent magnetic field, releasing the brake due to spring force. Except for the minimal force exerted by the segmental springs, the braked shaft is not exposed to any other axial force.