Unique in its Form: Inductive Heating Systems

Our inductive heating systems require only a few minutes of heat-up time and can reduce energy consumption by up to 50%. They ensure homogeneous temperature distribution and operate entirely emission- and CO₂-free. The heating patterns of the inductors are precisely reproducible — guaranteeing maximum process reliability. Upon request, we manufacture our inductive heating systems as customized solutions.

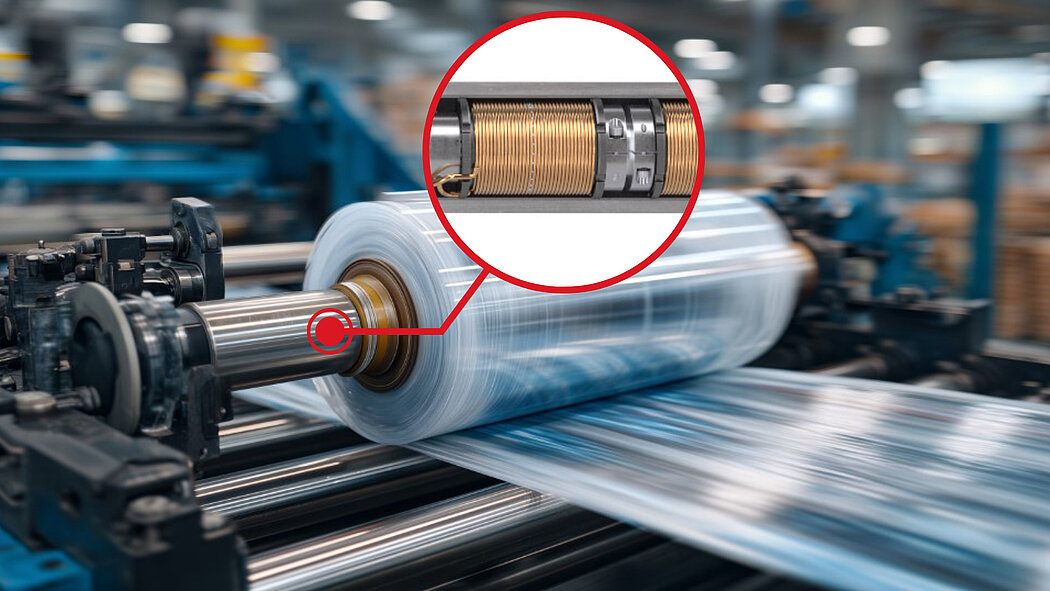

Applications for our inductive heating systems currently range from synthetic fiber production and roller heating for printing, embossing, and paper processing to food production (e.g., waffle baking machines).

With increasing electrification, more applications will follow. Our customers can rely on our many years of experience and invest in the future, says Hauke Ramm, Project / Product Manager Control Technology in Malente.

The generators, designed for installation in control cabinets, can operate multiple inductors simultaneously. Various fieldbus interfaces — such as Profinet or EtherCAT — are available for integration into machine control systems. The short heat-up time of inductive heating systems enables extremely high machine availability. The multi-zone design of the inductors ensures even heating of flat or cylindrical tools and allows targeted heating of individual zones. The inductors heat tools up to 350 °C and achieve an efficiency of over 95%. Since the heating systems operate without maintenance or wear, they offer an exceptionally long service life.

To perfectly adapt our heating systems to the application, we use numerical simulations of thermodynamic processes, among other methods. Together with the customer, we then develop the best possible heating solution based on a joint process analysis.

By using inductive heating systems, users can save up to 50 percent energy compared to gas heating. Another advantage is the maintenance-free operation: no media change is required, nor do slip rings need to be replaced. In addition, companies can significantly reduce their CO₂ emissions with our inductors.

But we don’t just supply these inductive heating systems — we also support users in integrating the inductors into their rollers. If a fully inductively heated roller is required, we can connect customers with partner companies that design and manufacture rollers according to their specifications — ready for installation and equipped with integrated Kendrion technology.

How does inductive heating fundamentally work?

It is based on the eddy current principle: High-frequency alternating current generates a magnetic alternating field, which is directed into the metal of the tool to be heated. This process produces eddy current losses that generate precisely controllable thermal energy.