Brakes

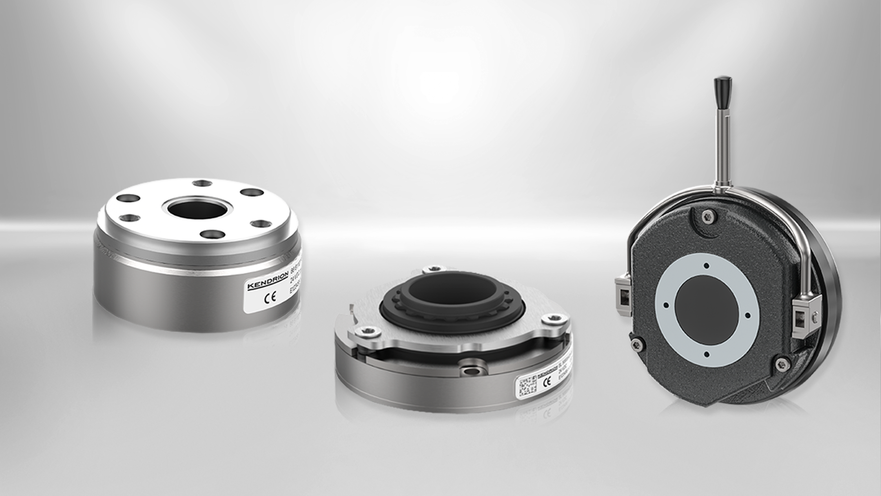

Electromagnetic actuated

Electromagnetically actuated brakes are designed to bring a moving load to a standstill and hold it (working brake) or to fix the position of an inactive load (holding brake). The activation (closing or opening) of the brake usually must happen in a split of a second to be able to brake loads quickly and safely in high-frequency applications.

Electromagnetic brakes are mainly used in electric motors, but also in integrated solutions. Applications include servo and geared motors, robotics, AGVs, industrial trucks, wind power, medical technology and many more. Depending on the application, either spring-applied brakes or permanent magnet brakes are used.

Products

(194)

show results as grid

show results as list

|

Title

ascending

descending

|

Type

ascending

descending

|

Brake size

ascending

descending

|

Torque (Nm)

ascending

descending

|

Torque definition

ascending

descending

|

Operation mode

ascending

descending

|

Nominal voltage (V)

ascending

descending

|

Nominal power (W)

ascending

descending

|

Max. switching energy per ES (J)

ascending

descending

|

Number of emergency stops

ascending

descending

|

Temperature range

ascending

descending

|

Max. rotation speed (depending on max. switching work during emergency stop) (min-1)

ascending

descending

|

E-Stop rotation speed (min-1)

ascending

descending

|

Backlash

ascending

descending

|

Thermal class

ascending

descending

|

IP Protection class

ascending

descending

|

Weight (kg)

ascending

descending

|

Brake type

ascending

descending

|

Armature type

ascending

descending

|

Hub type

ascending

descending

|

Hand release

ascending

descending

|

Counter friction part

ascending

descending

|

PWM control

ascending

descending

|

Outer diameter (mm)

ascending

descending

|

Lenght (mm)

ascending

descending

|

Hub diameter (mm)

ascending

descending

|

Keyway

ascending

descending

|

Pitch circle front side (mm)

ascending

descending

|

Pitch circle flange side (mm)

ascending

descending

|

Product Line

ascending

descending

|

Total work (kJ)

ascending

descending

|

Inner diameter (mm)

ascending

descending

|

Nominal power (releasing / holding) (W)

ascending

descending

|

Nominal voltage (releasing / holding) (V)

ascending

descending

|

Details | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

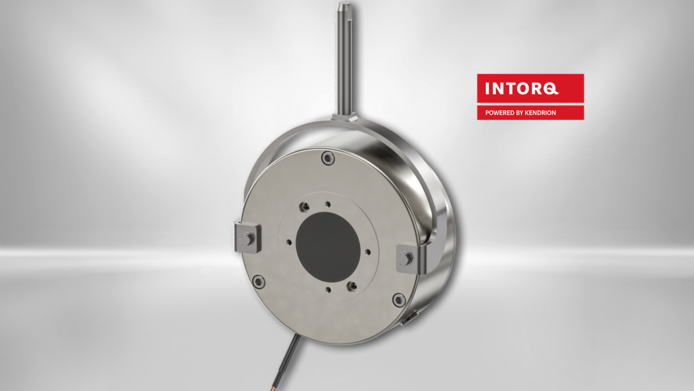

Spring Applied Brake - INTORQ BFK470

|

BFK470-14 | 14 | 110 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 60 | 30000 | 500 | -20...40°C, -40...40°C | 3600 | 3600 | - | F | IP66 | 8, 9 | - | - | - | Optional | Flange | possible | 168 | 73, 1 | 20, 22, 24, 25, 28, 30 | DIN 6885 | - | 145 | BFK470 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK470

|

BFK470-16 | 16 | 80 | M2/MK (dynamic) | Operating Brake | 24, 103, 180, 205 | 68 | 36000 | - | -20...40°C, -40...40°C | 3600 | 3600 | - | F | IP66 | 13, 7 | - | - | - | Optional | Flange | possible | 200 | 79, 1 | 22, 25, 28, 30, 32, 35, 38 | DIN 6885 | - | 170 | BFK470 | 966000 | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK470

|

BFK470-16 | 16 | 150 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 68 | 36000 | 500 | -20...40°C, -40...40°C | 3600 | 3600 | - | F | IP66 | 13, 7 | - | - | - | Optional | Flange | possible | 200 | 79, 1 | 22, 25, 28, 30, 32, 35, 38 | DIN 6885 | - | 170 | BFK470 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK470

|

BFK470-18 | 18 | 150 | M2/MK (dynamic) | Operating Brake | 24, 103, 180, 205 | 85 | 60000 | - | -20...40°C, -40...40°C | 3600 | 3600 | - | F | IP66 | 20 | - | - | - | Optional | Flange | possible | 226 | 89, 1 | 25, 28, 30, 32, 35, 38, 40, 42, 45 | DIN 6885 | - | 196 | BFK470 | 1542000 | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK470

|

BFK470-18 | 18 | 250 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 85 | 60000 | 500 | -20...40°C, -40...40°C | 3600 | 3600 | - | F | IP66 | 20 | - | - | - | Optional | Flange | possible | 226 | 89, 1 | 25, 28, 30, 32, 35, 38, 40, 42, 45 | DIN 6885 | - | 196 | BFK470 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK552

|

BFK552-12 | 12 | 60 | M2/MK (dynamic) | Holding Brake | - | - | 24000 | 20 | -20...50°C, -30...50°C | 3600 | 3600 | - | F | IP66 | 4, 7 | - | - | - | Optional | Flange | possible | 185 | 43, 7 | 20, 25 | DIN 6885 | - | 168, 3 | BFK552 | - | - | 84/37.3, 80/45 | 36/24 V, 48/36 | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-06 H | 06 | 4 | M4 (static) | Holding Brake | 24, 103, 180, 205 | 20 | 3000 | 100 | -20...50°C | - | 6000 | - | F | IP00, IP55 | 0, 86 | - | - | - | Optional | Flange / Friction Disc | possible | 83 | 35, 4 | 11, 12, 14, 15 | DIN 6885 | - | 72 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-08 H | 08 | 8 | M4 (static) | Holding Brake | 24, 103, 180, 205 | 25 | 7500 | 100 | -20...50°C | - | 5000 | - | F | IP00, IP55 | 1, 34 | - | - | - | Optional | Flange / Friction Disc | possible | 103 | 38, 4 | 11, 12, 14, 15, 20 | DIN 6885 | - | 90 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-10 H | 10 | 16 | M4 (static) | Holding Brake | 24, 103, 180, 205 | 27 | 12000 | 100 | -20...50°C | - | 4000 | - | F | IP00, IP55 | 2, 58 | - | - | - | Optional | Flange / Friction Disc | possible | 127 | 47, 2 | 11, 12, 14, 15, 20 | DIN 6885 | - | 112 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-12 H | 12 | 32 | M4 (static) | Holding Brake | 24, 103, 180, 205 | 40 | 24000 | 100 | -20...50°C | - | 3600 | - | F | IP00, IP55 | 3, 77 | - | - | - | Optional | Flange / Friction Disc | possible | 147 | 50, 3 | 20, 25 | DIN 6885 | - | 132 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-06 | 06 | 5 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 20 | 3000 | 100 | -20...50°C | - | 6000 | - | F | IP00, IP55 | 0, 86 | - | - | - | Optional | Flange / Friction Disc | possible | 83 | 35, 4 | 11, 12, 14, 15 | DIN 6885 | - | 72 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-08 | 08 | 10 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 25 | 7500 | 100 | -20...50°C | - | 5000 | - | F | IP00, IP55 | 1, 34 | - | - | - | Optional | Flange / Friction Disc | possible | 103 | 38, 4 | 11, 12, 14, 15, 20 | DIN 6885 | - | 90 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-10 | 10 | 20 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 27 | 12000 | 100 | -20...50°C | - | 4000 | - | F | IP00, IP55 | 2, 58 | - | - | - | Optional | Flange / Friction Disc | possible | 127 | 47, 2 | 11, 12, 14, 15, 20 | DIN 6885 | - | 112 | BFK557 | - | - | - | - | to the product |

|

Spring Applied Brake - INTORQ BFK557

|

BFK557-12 | 12 | 40 | M2/MK (dynamic) | Holding Brake | 24, 103, 180, 205 | 40 | 24000 | 100 | -20...50°C | - | 3600 | - | F | IP00, IP55 | 3, 77 | - | - | - | Optional | Flange / Friction Disc | possible | 147 | 50, 3 | 20, 25 | DIN 6885 | - | 132 | BFK557 | - | - | - | - | to the product |

|

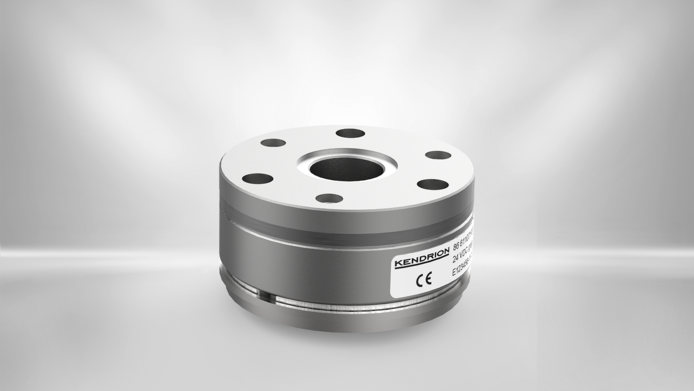

Permanent Magnet Brake - PM Line

|

86 61103H00-0001 | 03 | 0.4 | M4 (static) | Holding Brake | 24 | 6.2 | 10 | 500 | -5°C...120°C | 16000 | 3000 | 0° | F | IP00 | 0.07 | 611 | 200 | - | - | - | possible | 28 | 18.2 | - | - | 22 | - | PM Line | 5 | 9 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61103H00-0011 | 03 | 0.4 | M4 (static) | Holding Brake | 24 | 6.2 | 10 | 500 | -5°C...120°C | 16000 | 3000 | 0° | F | IP00 | 0.07 | 611 | 300 | - | - | - | possible | 28 | 26.7 | 8 | - | 22 | - | PM Line | 5 | 9 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61104H00-0022 | 04 | 2.2 | M4 (static) | Holding Brake | 24 | 8 | 200 | 500 | -5°C...120°C | 12000 | 3000 | 0° | F | IP00 | 0.19 | 611 | 200 | - | - | - | possible | 39.5 | 26.1 | - | - | 32.5 | - | PM Line | 100 | 13 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61104H00-0025 | 04 | 2.2 | M4 (static) | Holding Brake | 24 | 8 | 200 | 500 | -5°C...120°C | 12000 | 3000 | 0° | F | IP00 | 0.19 | 611 | 300 | - | - | - | possible | 39.5 | 41.1 | 8 | yes | 32.5 | - | PM Line | 100 | 13 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61104H00-0031 | 04 | 2.2 | M4 (static) | Holding Brake | 24 | 8 | 200 | 500 | -5°C...120°C | 12000 | 3000 | 0° | F | IP00 | 0.19 | 611 | 400 | - | - | - | possible | 39.5 | 29.6 | 8 | yes | 32.5 | - | PM Line | 100 | 13 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61106H00-0020 | 06 | 3.2 | M4 (static) | Holding Brake | 24 | 12 | 350 | 500 | -5°C...120°C | 10000 | 3000 | 0° | F | IP00 | 0.3 | 611 | 200 | - | - | - | possible | 56 | 24 | - | - | 48 | - | PM Line | 175 | 24 | - | - | to the product |

|

Permanent Magnet Brake - PM Line

|

86 61106H00-0046 | 06 | 3.2 | M4 (static) | Holding Brake | 24 | 12 | 350 | 500 | -5°C...120°C | 10000 | 3000 | 0° | F | IP00 | 0.3 | 611 | 300 | - | - | - | possible | 56 | 41 | 15 | yes | 48 | - | PM Line | 175 | 24 | - | - | to the product |