Induction heating may not be a new technology, but it is increasingly earning its place amongst industries and manufacturers looking to transition their processes to more sustainable energy. This blog looks at the benefits and applications, and how Kendrion supports manufacturers to make the change.

The need to find more sustainable approaches to energy is something that touches us all, at every level. From our homes to our industries, we have to make the most of technologies that support the much-needed transition to greener forms of energy.

Induction heating is one such technology, and offers important benefits all along the line. It doesn’t consume fossil fuels or produce hazardous emissions or carbon dioxide (CO2) -making it an excellent alternative to oil- and gas-driven processes. Furthermore, it’s energy efficient, highly accurate, extremely safe, and fits a seemingly endless range of industrial applications.

So how does it work?

Induction heating is afast, repeatable, non-contact way to heat up metals, especially ferrous metals.An induction coil is subjected to a high-frequency alternating current, which creates an electromagnetic field. The material to be heated (the ‘workpiece’) is placed inside this field, and the eddy currents generated create heat directly in the workpiece.

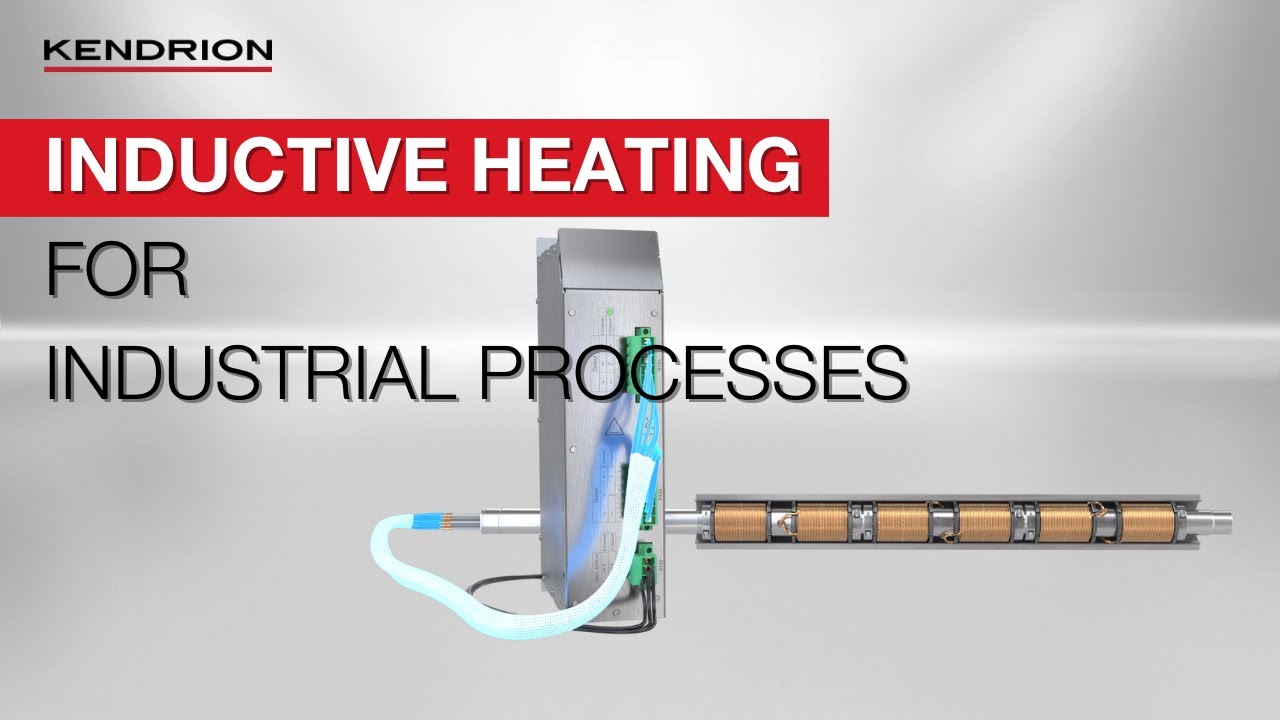

An industrial induction heating system usually consists of an induction generator and a coil, also known as an inductor. With Kendrion's Modular Heating System, systems with up to seven generators and 42 inductors can be built.

This technology is hardly new: scientists have been using the concept to melt metals since 1916. So why has it become even more interesting for industrial players looking to transition to greener energy?

The advantages of induction

In addition to the sustainability benefits mentioned above, induction heating offers plenty of productivity advantages, as well:

It’s fast. The desired process temperatures are reached in the shortest possible time thanks to high area output and low required masses for typical workpieces.

It’s accurate. By designing the inductors and using multiple heating zones, a very accurate surface temperature can be achieved.

It’s easily controllable. You can use convertors and process control software to control the entire heating process.

It’s repeatable. You can duplicate process parameters such as temperature, heat-up times, heat pattern and more.

It’s clean, accurate and safe. You can convert up to 90% of the energy expended into useful heating, without burning fossil fuels.

What is it being used for?

The technology of our induction heating systems is designed for applications in the food processing, textile, printing and paper industries. It is used in machines where process heat is required, for example for heating rolls or tools.

Induction heating fits well with Kendrion’s commitment to support the transformation of industries to greener forms of energy. We have been successfully developing induction heating systems for 20 years; today more than 70,000 of our heating systems are driving textile, food preparation and printing processes, globally.

Helping OEMs transition to induction technology

Despite the benefits, the switch to a new heating process can be daunting for many smaller OEMs. We help make it smooth and straightforward, with expert engineering support and product flexibility.

For example, our induction heating systems are compact and easy to integrate. They generally include a controller and up to seven stackable induction generators. The controller can be integrated directly into the control of a machine via a fieldbus interface. A central controller drives and monitors performance of all generators. Depending on the configuration, it can also control the heating channels with integrated PID controllers. The units are designed for installation in control cabinets.

Based on our experience working with customers in many fields, we have built a brand-new induction system platform. It enables us to produce new product variants quickly and in large volumes, without requiring major R&D time and cost. Because of the modular design of our products, we can also offer a high level of customization. For instance, we can adapt the induction coils to suit practically a variety of workpieces, to deliver optimal heat patterns with minimal energy consumption.

With more and more applications for induction heating appearing, at Kendrion, too, we are exploring new horizons. For example, we are working with a new customer on a novel application: an industrial waffle-baking machine. We have also won the contract for a customized heating system for an automotive battery manufacturing machine. Clearly, induction heating is finding its place in very diverse sectors!

Maybe it’s time to explore the possibilities for your own activities. If you are looking for ways to transition your manufacturing processes to greener energy, while increasing safety, efficiency, and productivity, we would be delighted to discuss how we can help you navigate this new technology and reap its many benefits.

Let's shape the future together!

With Kendrion you have a future-oriented partner at your side.

Learn more about our induction heating systems.