Why SI/PI Matters in Modern PCB Design

Modern PCAs (Printed Circuit Assemblies) often include high-speed signals and tightly packed components. This makes them vulnerable to issues such as crosstalk, voltage drop, or impedance mismatches – problems that may not appear until late in development unless simulations are used early on.

By simulating signal and power behavior before a physical prototype exists, we can predict – and avoid – potential performance issues. That’s where ANSYS comes in.

From Virtual Model to Optimized Design

Using ANSYS, we model the electronic behavior of critical subsystems to validate and improve our designs. Two main types of analyses are typically used:

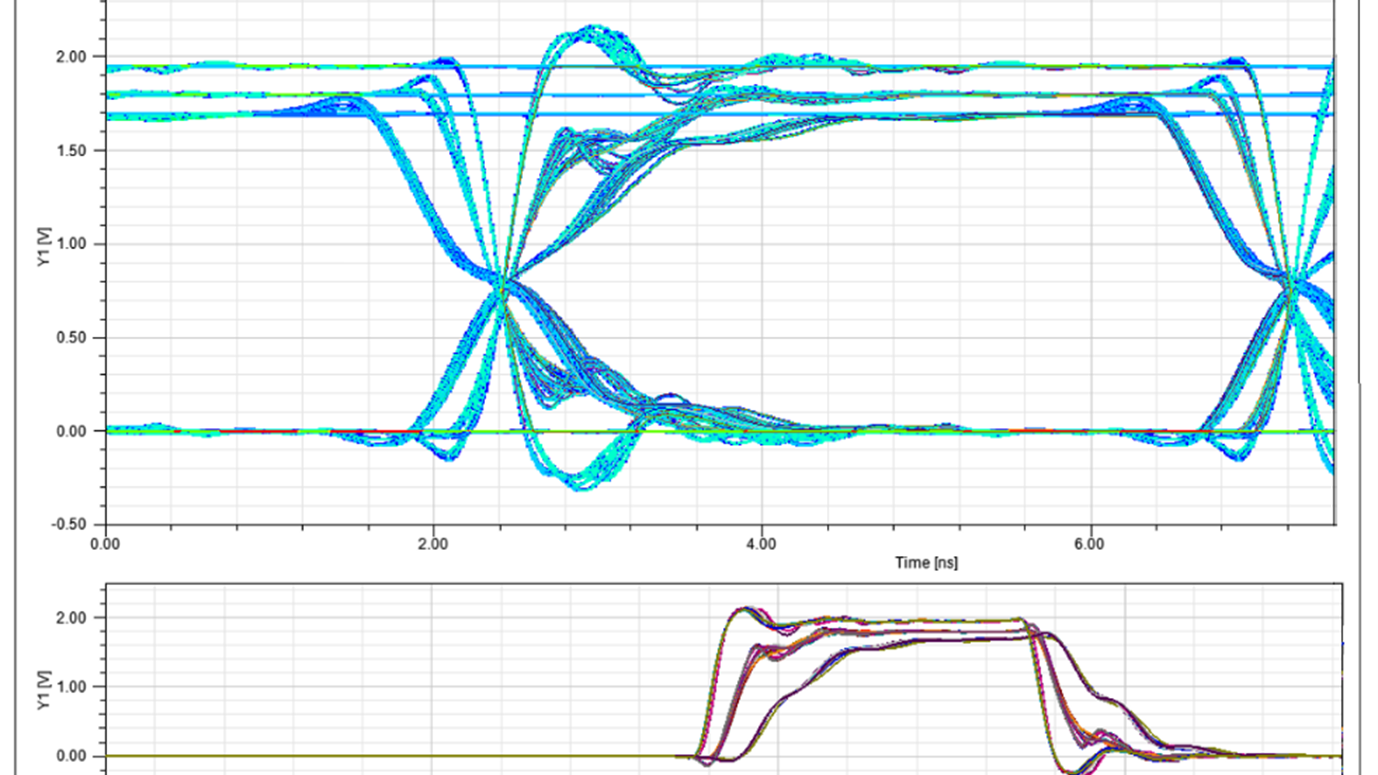

Signal Integrity (SI) Simulation

We identify unwanted effects like crosstalk and reflections in high-speed nets. By adjusting driver configurations or rerouting traces, we can drastically reduce noise and ensure clean, reliable signals across the board.Power Integrity (PI) Simulation

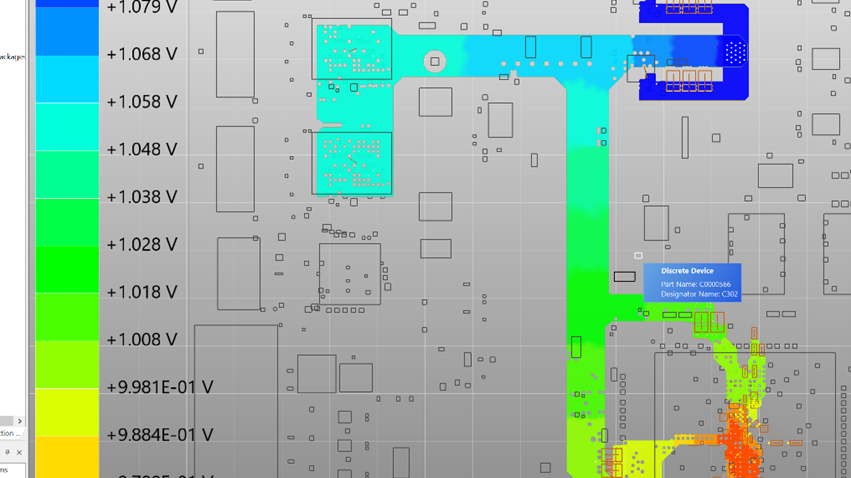

Low-voltage components are sensitive to even small fluctuations. PI simulation helps us minimize voltage drops across the power delivery network (PDN), ensuring each component receives the power it needs, consistently and reliably.

“With ANSYS, we can visualize and fix potential issues that would otherwise be invisible until hardware testing – saving time, and costs, while increasing quality of the end product.”

Detecting Problems Before They Appear

For example, by running a voltage ripple simulation between power and ground planes, we can uncover causes of signal degradation. Or, by analyzing crosstalk between adjacent nets, we spot weak points in the layout where small adjustments lead to significant gains in performance.

Even subtle design errors – like an overlooked via or trace proximity – can be caught in simulation and corrected early.

Faster Development, Higher Confidence

Simulations reduce the number of physical prototypes required and avoid costly redesigns. This shortens time to market and increases overall product quality. It also gives our customers peace of mind: their design is already optimized before a single PCB is produced.

More than Just SI/PI

In addition to signal and power integrity, we use ANSYS to simulate thermal behavior, electromagnetic fields, and mechanical effects. This allows us to provide a holistic design service that meets demanding performance and compliance requirements.

Facing a Complex Design Challenge?

At 3T, we’re ready to tackle your toughest design problems using the power of simulation. With deep experience in electronics development and ANSYS tools, we help you get it right from the start.